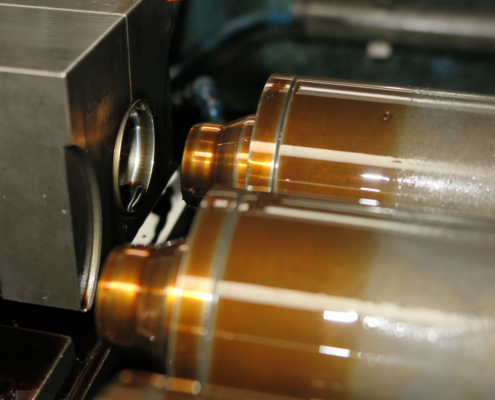

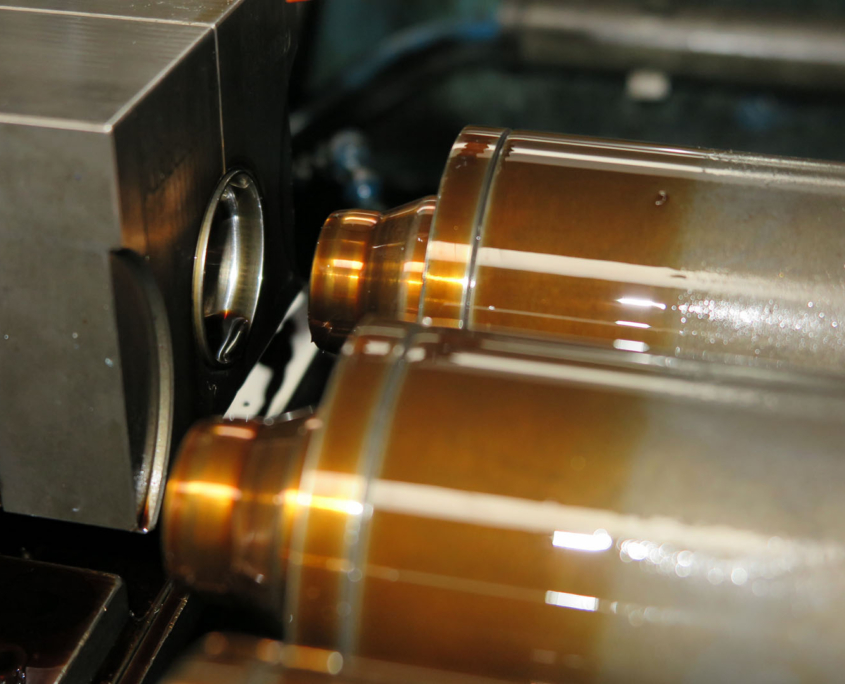

Tube swaging and tapering

GAMMA 3 offers tube swaging and tube tapering, as well as tube flaring, tube end expansion, tube flanging, tube shaping and forming, and other similar deformation processes.

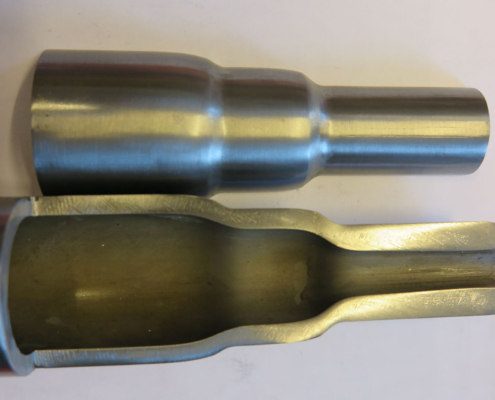

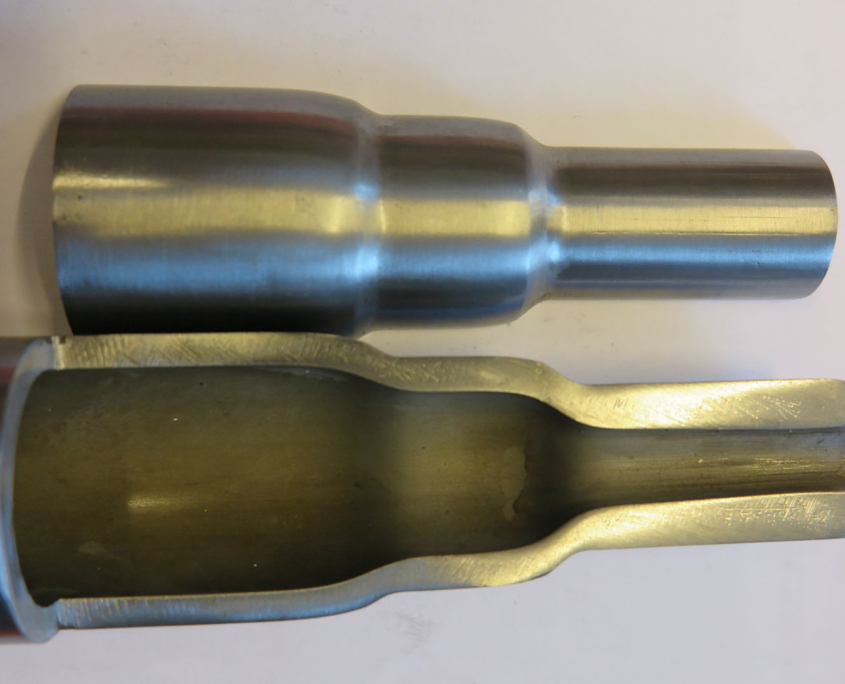

Doing a pipe and tube swaging or tube tapering means changing the diameter and shape, for a short stretch of length, while for tube flaring and tube end expansion you only work on the end of the pipe.

Keep reading

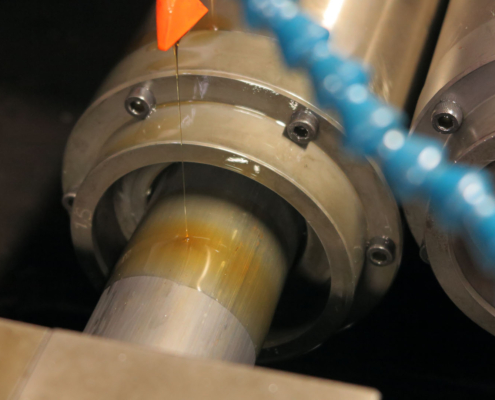

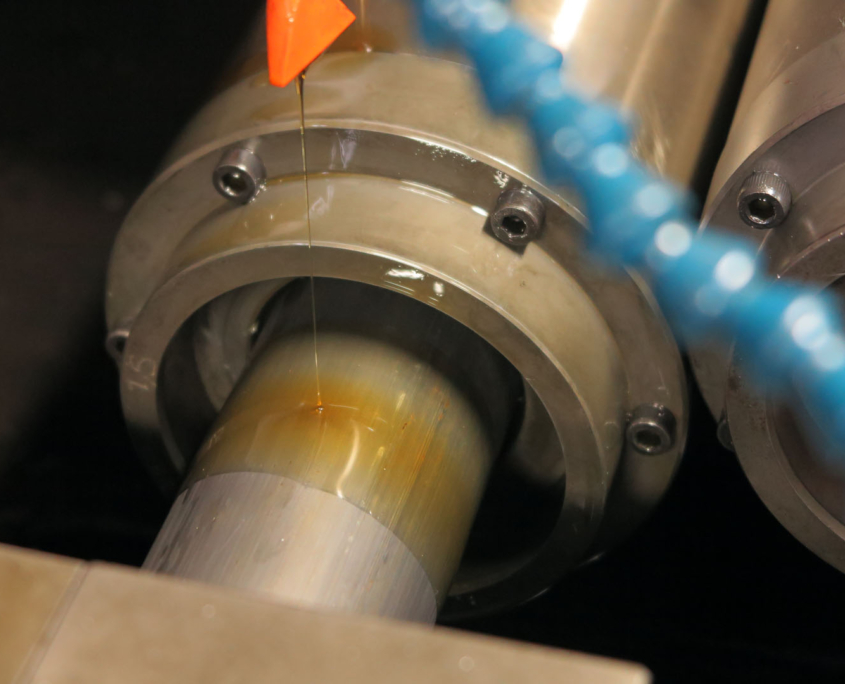

Both the tube swaging and tube tapering processes are obtained without heating, with dies, pins, punches and tools.

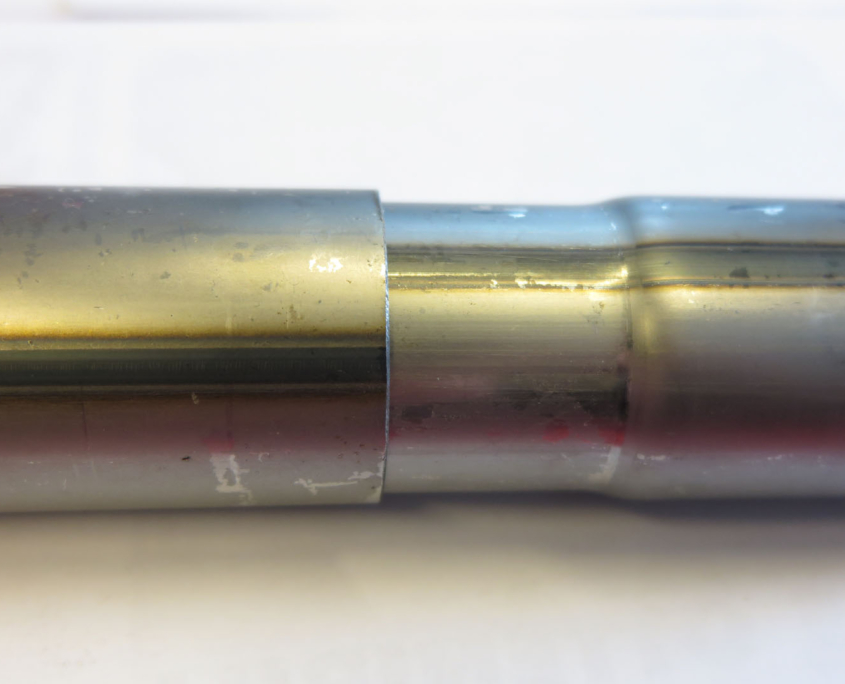

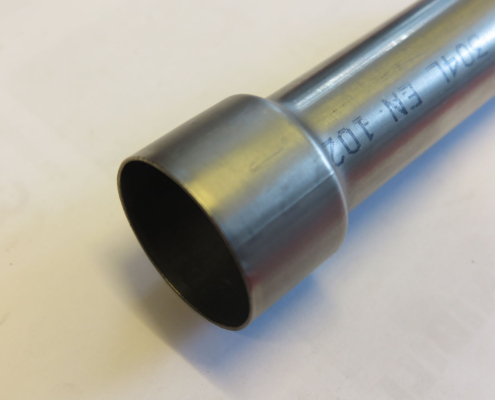

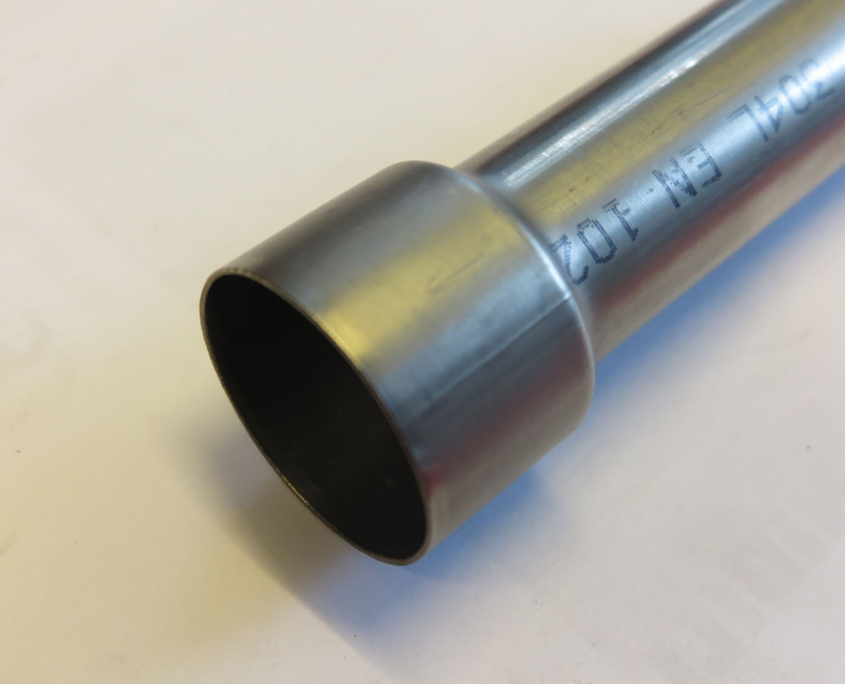

During tube swaging, a bottleneck is thus created with a radius of connection, which decreases the diameter of the tube, and which then continues in a constant shape, while in tube end expansion it is the exact opposite.

In tube swaging and tube tapering processes, it is possible to obtain different constant diameters, cylindrical and conical, with our modern machine tools for tube swaging and tube expansion.

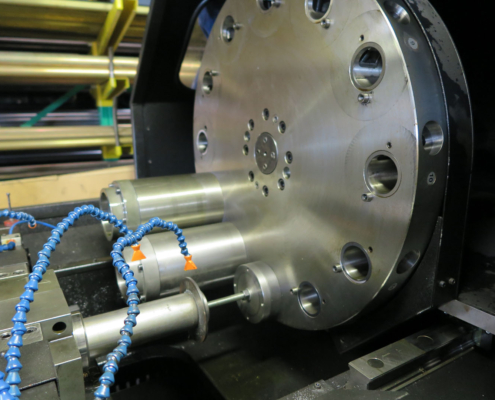

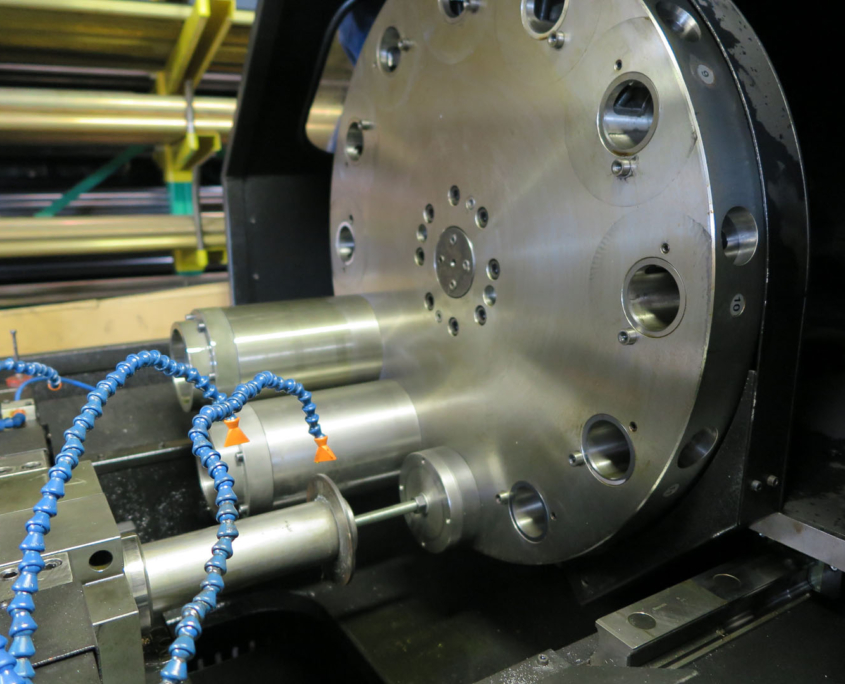

These CNC numerical control machines allow you to work with high precision, and above all with constancy and repeatability, to guarantee the quality of the products reserved for customers.

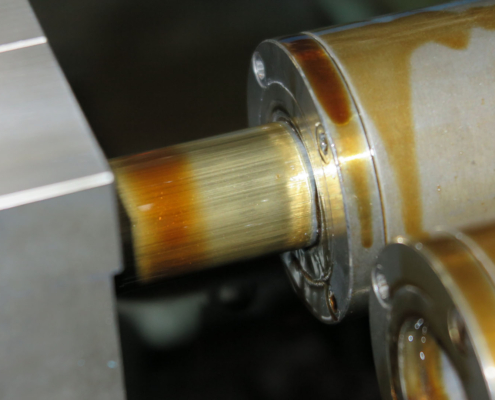

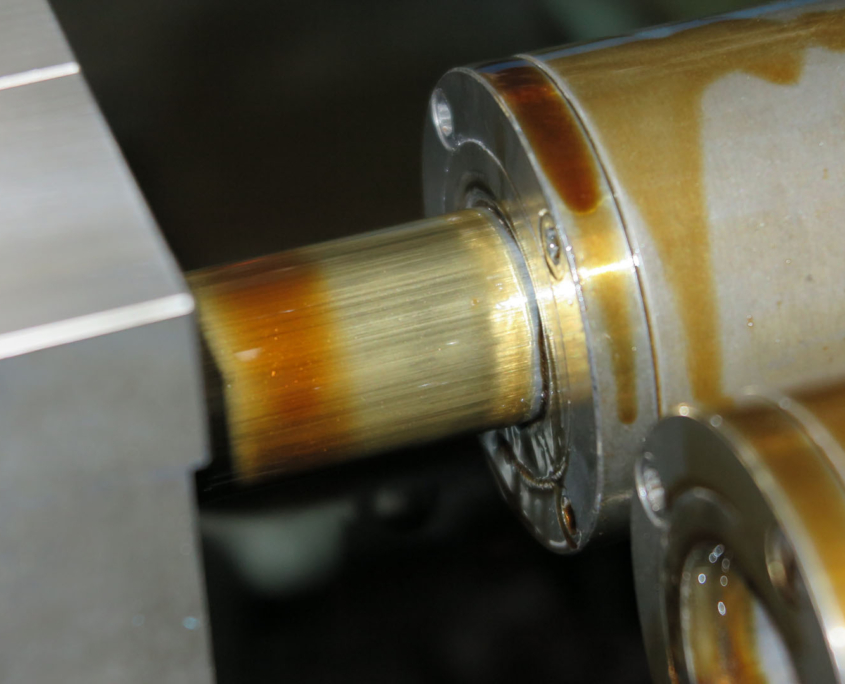

The company also has an exclusive machinery in its size for third party work.

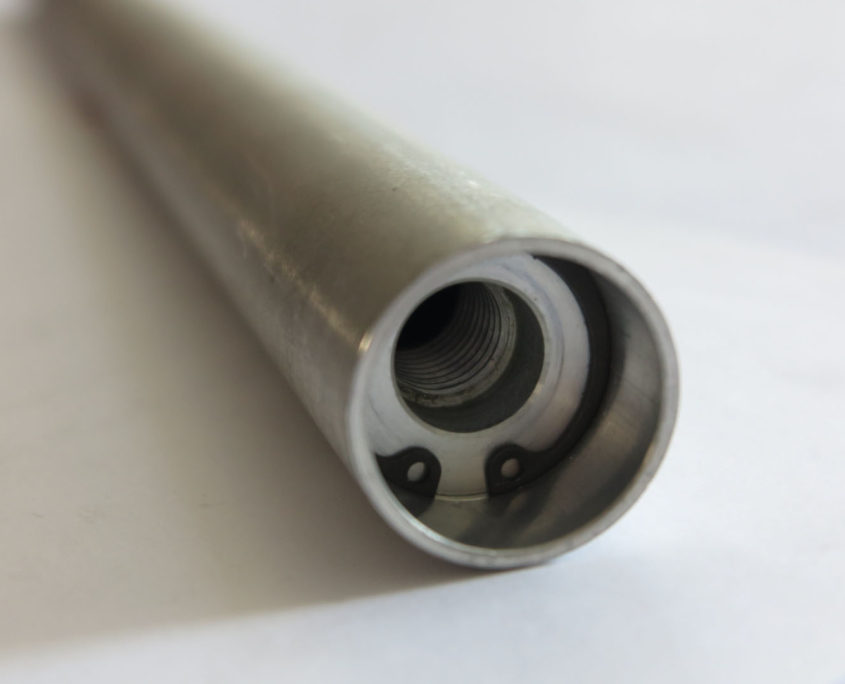

This machine can do tube swaging, tube tapering, tube widening, tube end expansion, tube flaring, and mechanical machining in general, on tube and pipes up to 160mm diameter and with a maximum thickness of 10mm, useful for processing urban poles, ducts, automotive and much more. The considerable thrust force in tons, and the latest generation CNC numerical control, allow to do mechanical processes of tubes not possible until recently.

Furthermore, thanks to the automated machines, both for cutting to length with an automatic cutting line, and for automated tube swaging and tube tapering machines, it is possible to have rapid delivery and competitive prices on large quantities, but small lots and samplings are also carried out.

The most frequent use of these processes is certainly the graft to insert a pipe into another of the same diameter.

With this tube swaging process, GAMMA 3 offers tubes for demountable structures, outdoor rods, table legs, chair legs, flag poles, urban lighting poles, mechanical couplings, nozzles for machinery, automotive components, tubular drive shafts, reductions for air ducts, the piping sector in general, and much more.

The possible materials to work with are iron, brass, aluminium, stainless steel, titanium, copper and silver.

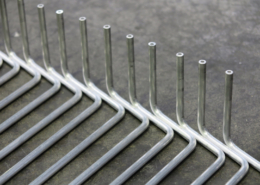

Swaged and tapered tubes are in great demand in the construction, nautical, plumbing, home and office furnishings, street furniture, fencing, urban lighting, automotive, carpentry, air conditioning, heating, plumbing, household appliance components and much more.

Tube swaging and tapering

GAMMA 3 offers tube swaging and tube tapering, as well as tube flaring, tube end expansion, tube flanging, tube shaping and forming, and other similar deformation processes.

Doing a pipe and tube swaging or tube tapering means changing the diameter and shape, for a short stretch of length, while for tube flaring and tube end expansion you only work on the end of the pipe.

Both the tube swaging and tube tapering processes are obtained without heating, with dies, pins, punches and tools.

During tube swaging, a bottleneck is thus created with a radius of connection, which decreases the diameter of the tube, and which then continues in a constant shape, while in tube end expansion it is the exact opposite.

In tube swaging and tube tapering processes, it is possible to obtain different constant diameters, cylindrical and conical, with our modern machine tools for tube swaging and tube expansion.

Keep reading

These CNC numerical control machines allow you to work with high precision, and above all with constancy and repeatability, to guarantee the quality of the products reserved for customers.

The company also has an exclusive machinery in its size for third party work.

This machine can do tube swaging, tube tapering, tube widening, tube end expansion, tube flaring, and mechanical machining in general, on tube and pipes up to 160mm diameter and with a maximum thickness of 10mm, useful for processing urban poles, ducts, automotive and much more. The considerable thrust force in tons, and the latest generation CNC numerical control, allow to do mechanical processes of tubes not possible until recently.

Furthermore, thanks to the automated machines, both for cutting to length with an automatic cutting line, and for automated tube swaging and tube tapering machines, it is possible to have rapid delivery and competitive prices on large quantities, but small lots and samplings are also carried out.

The most frequent use of these processes is certainly the graft to insert a pipe into another of the same diameter.

With this tube swaging process, GAMMA 3 offers tubes for demountable structures, outdoor rods, table legs, chair legs, flag poles, urban lighting poles, mechanical couplings, nozzles for machinery, automotive components, tubular drive shafts, reductions for air ducts, the piping sector in general, and much more.

The possible materials to work with are iron, brass, aluminium, stainless steel, titanium, copper and silver.

Swaged and tapered tubes are in great demand in the construction, nautical, plumbing, home and office furnishings, street furniture, fencing, urban lighting, automotive, carpentry, air conditioning, heating, plumbing, household appliance components and much more.